What are the application scenarios of WHC280 worm gear reducer in the finished product processing stage

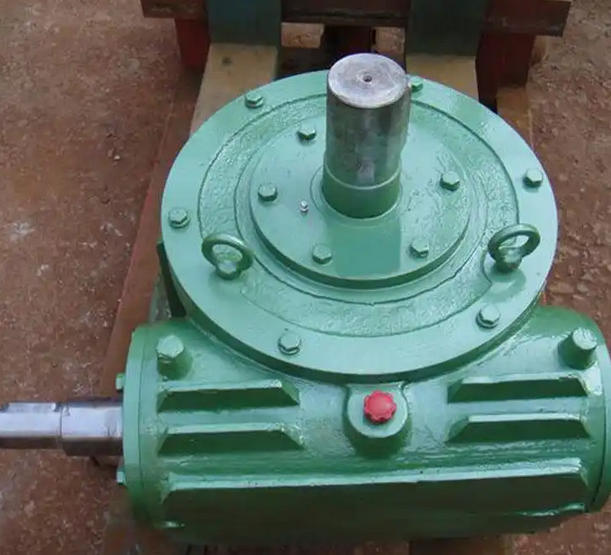

WHC280 is a large-sized circular cylindrical worm gear reducer with strong rigidity, high output torque, and smooth transmission. It is suitable for low-speed heavy load, precise start stop, and stable speed operation in finished product processing. It focuses on core workstations such as heavy-duty conveying, finished product shaping, palletizing and packaging, sorting and transportation, and is suitable for the entire process of finished product processing in multiple industries such as machinery, metallurgy, building materials, and light industry1. Core applications for heavy-duty transportation of finished products (adaptation core: high torque, low-speed stability, impact resistance, suitable for heavy-duty finished product transportation)

1.1 Heavy duty finished product roller conveyor drive: heavy-duty finished product roller conveyor line drive for metallurgical plates/profiles, heavy machinery components, cement products, stone products, etc. WHC280 high torque output is suitable for heavy-duty conveying needs, low-speed operation ensures smooth transportation of finished products, avoids collisions and scratches, and is suitable for pre shipment conveying and inter process transfer stations of finished products

1.2 Finished product climbing belt conveyor drive: The climbing belt conveyor drive for large finished products (such as home appliance casings, furniture boards, and packaging carton stacks) can overcome climbing resistance with high torque, ensuring smooth transmission without slipping and low-speed operation to prevent finished products from slipping. It is suitable for lifting, transportation, warehousing, and feeding after finished product processing

1.3 Finished product screw conveyor drive: Large screw conveyor drive for granular and block shaped products (such as feed particles, plastic particles, and ore products), suitable for long-distance and large-diameter screw loads, low-speed output to ensure quantitative conveying, avoid product breakage, and adapt to the conveying process before finished product measurement and packaging

2. Finished product shaping and finishing applications (adaptation core: precise speed regulation, stable speed operation, reliable positioning, ensuring finished product processing accuracy)

2.1 Finished product surface polishing drive: Large board, profile, hardware accessory finished product surface polishing machine, polishing machine drive, low-speed stable speed operation to ensure uniform polishing, no surface defects caused by speed fluctuations in finished products, high torque to adapt to changes in polishing load, and to adapt to the finishing process of metal, stone, and wood products

2.2 Finished product straightening and shaping drive: The straightening machine for pipes and profiles, as well as the actuator drive of the shaping machine, operate at low speed to achieve precise straightening and shaping. The large rigid body is resistant to impact and is suitable for finished product size correction and shape straightening workstations, ensuring that the precision of the finished product meets the standard

2.3 Finished product edge cutting and chamfering drive: feed drive for large sheet metal and casting finished edge cutting and chamfering machines, low-speed precise control of feed speed, high torque to meet cutting load, smooth operation to avoid cutting deviation, suitable for corner processing and size refinement after finished product processing