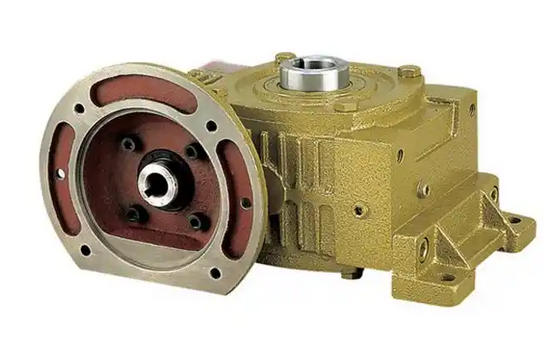

What is the impact of oil pool depth on the noise of QJRS-D-450-80-I gear reducer

QJRS-D-450-80-I, as a heavy-duty gear reducer, usually uses oil immersion lubrication in an oil tank. The depth of the oil tank affects the immersion depth, which in turn has a significant impact on the operating noise from the aspects of oil stirring resistance and lubrication effect. Both shallow and deep can cause abnormal noise increase. Only when it is at a reasonable depth can the equipment maintain low-noise operation, as follows:The oil pool is too shallow

1. Prominent meshing noise: A shallow oil pool can result in insufficient oil immersion depth of the gears, making it impossible to ensure the formation of a stable and complete oil film on the tooth surface. This can lead to boundary friction or even dry friction during gear meshing. Originally, the oil film could buffer the impact of meshing. Without the oil film, direct or semi contact between the tooth surface metal will produce obvious "friction sounds". If this continues for a long time, it will cause pitting and wear on the tooth surface, accompanied by periodic "knocking sounds". At the same time, a shallow oil pool means that there is less oil, making it difficult to cover components such as bearings with splash lubrication. Running bearings without oil will produce high-frequency abnormal sounds such as continuous rustling.

2. Impurities cause additional noise: When the depth of the oil pool is insufficient, it is difficult for the gears to rotate and form a stable oil flow, and impurities such as sludge and metal debris deposited at the bottom of the tank are easily stirred up by the gears. These impurities entering the gear meshing area and the interior of the bearing can cause local impact and grinding, mixing irregular noise into the noise, and the noise amplitude will gradually increase with the increase of impurities.

The oil pool is too deep

1. The noise of oil stirring significantly increases: The large gear size and rotational inertia of this type of reducer are large, and the oil pool is too deep, which will cause the gear to be immersed in oil beyond the standard depth. When the gear rotates at high speed, it needs to overcome great oil resistance. Intense oil stirring not only generates a large amount of oil turbulence and bubbles, but also causes low-frequency noise of "buzzing". Especially during high-speed operation, this oil stirring noise will sharply increase with the increase of speed. Relevant tests show that when the oil level is too high, the oil stirring loss increases and may also be accompanied by cavitation sound.

2. The risk of resonance noise increases: An excessively deep oil pool can lead to an excessive amount of oil, poor oil convection, and difficulty in dissipating the heat generated by gear stirring, resulting in an increase in oil temperature. Excessive oil temperature can decrease the viscosity of the oil and may cause slight thermal deformation of the casing, affecting the accuracy of gear meshing and bearing clearance. When the gear meshing frequency approaches the natural frequency of the casing due to these changes, it will cause structural resonance, significantly increasing the overall noise level. In severe cases, it will also be accompanied by intensified casing vibration, further amplifying the noise.

3. Usually, the recommended oil immersion depth for this type of heavy-duty gear reducer is 1-2 tooth heights, which can avoid noise problems caused by shallow or deep oil pools. During high-speed operation, the oil immersion depth can be appropriately reduced to about 0.7 times the tooth height, but at least a 10mm oil immersion depth should be ensured to balance lubrication effect and noise reduction requirements.