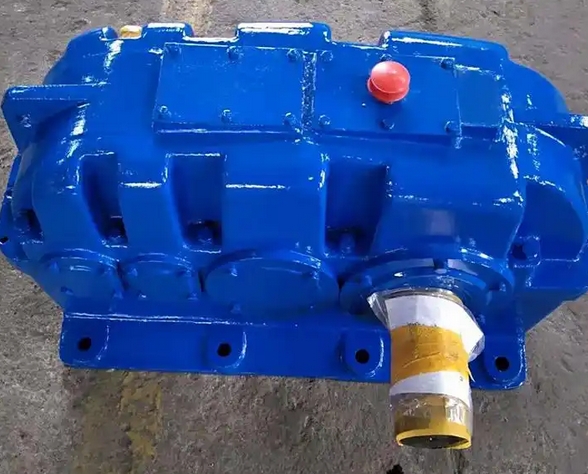

How to maintain FAF107-50.73-15KW hard tooth gear reducer to ensure that its noise and vibration levels meet the standards

To ensure that the noise and vibration levels of the FAF107-50.73-15KW hard tooth gear reducer meet the standards, maintenance can be carried out from the following aspects:Regular inspection and monitoring

Operation status inspection: During daily operation, it is necessary to closely monitor whether there is any abnormal noise, vibration, or heating in the gearbox. Once any abnormalities are found, the machine should be stopped for inspection in a timely manner.

Inspection of connecting components: Check if the connecting bolts are tightened to ensure the normal operation of the transmission device and prevent increased vibration and noise caused by loose bolts.

Vibration monitoring: Use vibration analysis tools to monitor the vibration level of the gearbox, such as vibration velocity, acceleration, and other parameters, and compare them with standard values to analyze whether there are potential faults.

Temperature monitoring: Monitor the operating temperature of the gearbox to ensure it is within the normal operating temperature range. Excessive temperature may be an early sign of gearbox failure and can affect noise and vibration levels.

lubrication management

Oil level inspection: Regularly check the oil level of the gearbox to ensure that it is within the normal range. If the oil level is too low, it will cause insufficient lubrication, increase wear and noise.

Oil quality inspection: Check the oil quality to ensure that the oil has not deteriorated, the oil color is clear, and there is no odor. Deteriorated lubricating oil cannot provide good lubrication and cooling effects, which can exacerbate component wear, cause noise and vibration.

Regular oil change: Replace lubricating oil regularly according to the manufacturer's recommendations and usage conditions. When replacing the lubricating oil, it should be ensured that the reducer has been completely cooled down, and the specified lubricating oil brand and model should be used. Different brands of lubricating oil may not be compatible.

Gear and bearing maintenance

Gear inspection: Regularly conduct comprehensive and detailed inspections of gears, focusing on the degree of wear and whether there are cracks, pitting, and other damages on the tooth surface. Once a problem is discovered, it should be repaired or replaced in a timely manner according to the actual situation to ensure the normal meshing of the gears and reduce noise and vibration.

Bearing maintenance: Lubricate the bearings according to the prescribed cycle and carefully inspect their operating condition for any abnormal noise, heating, looseness, or other phenomena. If there are signs of damage to the bearings, they should be replaced immediately to ensure smooth rotation and reduce vibration and noise.

Installation and alignment adjustment

Installation inspection: Check whether the installation of the reducer is stable and whether the anchor bolts are loose. Unstable installation can cause additional vibration and noise during operation of the gearbox, so it is necessary to ensure that the gearbox is installed on a sturdy and horizontal foundation.

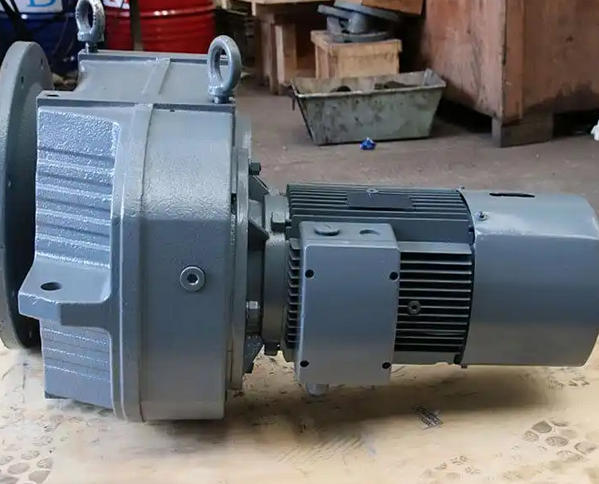

Centering adjustment: ensure the centering accuracy between the reducer and the drive motor or other related equipment, and use professional centering tools for detection and adjustment. Poor alignment can generate additional force and torque during power transmission, leading to vibration and noise.