Application and maintenance of GV/CV vertical gear reduction motor in the food processing industry

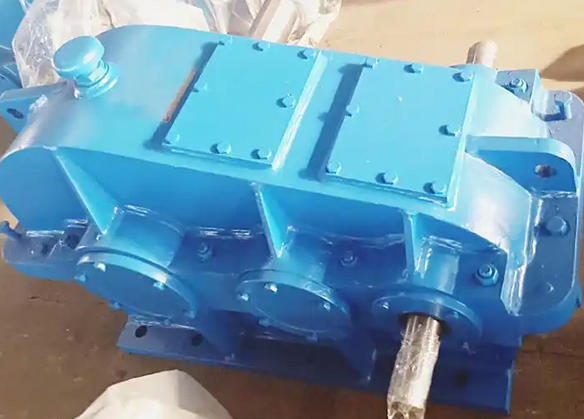

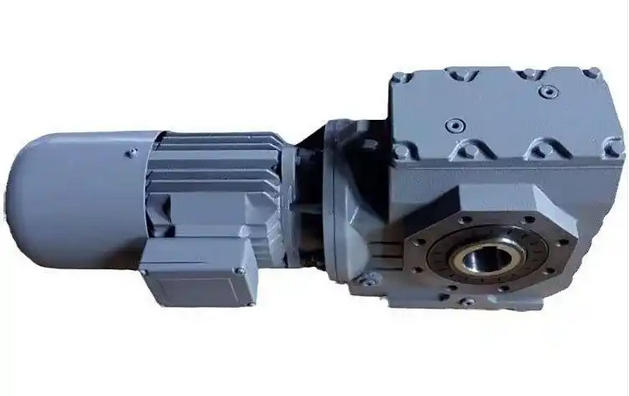

The core component of GV/CV vertical gear reduction motor is a precise gear system, which can effectively convert the high-speed torque generated by the motor operation into rotational power with high torque and low speed through the action of reduction gears. The design of this gear system is unique and refined, with excellent durability and stability to ensure the reliability and efficiency of equipment operation. In the food processing industry, GV/CV vertical gear reduction motors play a crucial role. Below are some specific examples to demonstrate its widespread application in this field.

In large bread production plants, GV/CV vertical gear reduction motors are used to drive dough mixers. These mixers require strong and stable power to thoroughly mix various ingredients to produce high-quality dough. The precise reduction ratio of the gear motor ensures that the mixer can mix at the appropriate speed and force, avoiding excessive or insufficient mixing. Meanwhile, the vertical installation method of the motor saves space and adapts to the compact layout of the factory.

On the automated production line of food processing plants, GV/CV vertical gear reduction motors drive conveyor belts to quickly and smoothly transport processed food to the next stage. The operating speed of this conveyor belt needs to be adjusted according to different production stages, and the gear reduction motor can easily achieve this speed change, ensuring the efficiency and smoothness of the production process.

In beverage canning production, GV/CV vertical gear reduction motor provides power for the filling machine. It ensures the accuracy and stability of the canning process, ensuring that the capacity of each bottle of beverage meets the standard requirements.

However, proper maintenance is essential to ensure the long-term stable operation of these motors.

In the above-mentioned bakery, maintenance personnel will conduct regular comprehensive inspections of the gear reduction motor. They will carefully clean the surface and surrounding dust and debris of the motor to prevent these pollutants from entering the interior of the motor, affecting its performance and even causing malfunctions. At the same time, they will replace the lubricating oil at regular intervals to ensure that key components such as gears and bearings receive good lubrication and reduce wear.

In the example of conveyor belt drive, maintenance personnel will pay special attention to the fastening of the connection between the motor and the conveyor belt. Regularly check whether the bolts are loose and tighten them in a timely manner to prevent transmission problems caused by loose connections. They will also monitor the operating temperature of the motor. Once an abnormal increase in temperature is detected, they will promptly shut down for inspection, identify the cause, and solve the problem to avoid damage to the motor due to overheating.