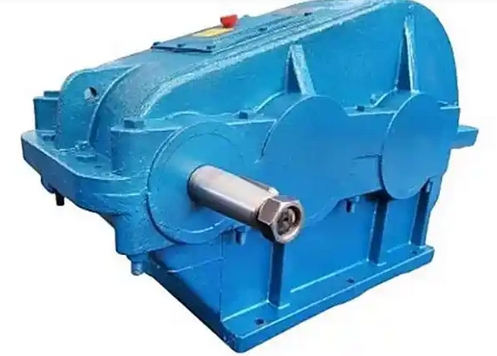

How to apply lubricating grease to ZQ500-23.34-3CA cylindrical gear reducer

When applying lubricating grease to the ZQ500-23.34-3CA cylindrical gear reducer, the following methods and precautions can be referred to:Preparation before application: Use appropriate mechanical cleaning agents and tools to thoroughly clean the parts of the gearbox that need to be lubricated, such as gears, bearings, etc., to ensure that there is no oil, dust, or impurities, and to avoid moisture entering the interior of the equipment.

Lubricating grease selection: 3 # industrial grease is commonly used for reducers, and medium load industrial gear oils such as L-CKC220 and L-CKC320 in GB5903 can also be selected according to the actual situation. For details, please refer to the reducer's user manual.

Application method: For the rolling bearings inside the reducer, filling method can be used. Use a specialized grease gun to inject grease into the bearing chamber, with a filling amount generally ranging from 1/3 to 1/2 of the bearing chamber space. For gear parts, if it is an open gear, lubricating grease can be evenly applied to the gear tooth surface to ensure that each tooth surface is covered; If it is a closed gear, lubricating grease is usually applied to the meshing area of the gear and the inner wall of the housing before assembly.

Application amount control: The injection amount should be immersed at 1/2 of the gear. Too much will increase operating resistance and cause temperature rise, while too little will not provide sufficient lubrication.

Attention: It is necessary to prevent the mixing of different types, grades, and old and new lubricating greases, and the grease containers and tools should not be used interchangeably. At the same time, the condition of the lubricating grease should be regularly checked, and it should be replenished or replaced in a timely manner according to usage to ensure good lubrication and normal operation of the gearbox.