What factors should be considered when choosing a hard tooth surface gear reducer or a soft tooth surface gear reducer

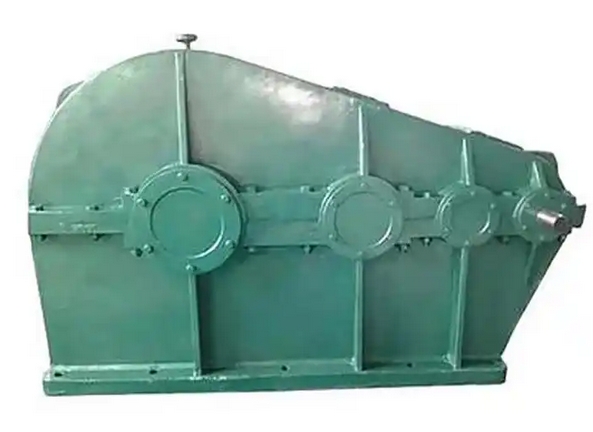

When choosing a hard tooth surface gear reducer or a soft tooth surface gear reducer, factors such as load conditions, working environment, speed requirements, noise limitations, installation space, and maintenance costs should be comprehensively considered, as follows: Load size: If the equipment needs to withstand heavy loads, such as mining crushers, metallurgical rolling mills, etc., a hard