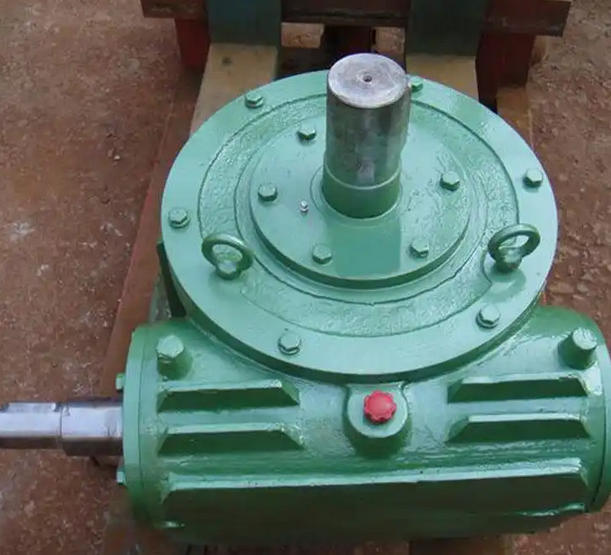

What are the precautions for adjusting the gear machining method of ZLY180-8-1 reducer

When adjusting the gears of ZLY180-8-1 reducer, remember these points to make it easier for you: 1、 Must check items before adjustment Mechanical connection: Use a torque wrench to check the anchor bolts and coupling bolts to ensure that they are not loose. Lubrication system: The oil level should be above the centerline of the oil gauge. If the oil is cloudy or contains metal debris, rep